At SOS Manufacturing, we design and manufacture custom wire harnesses and cable assemblies. We prioritize on-time delivery and quality products to satisfy and build long-term relationships with our customers. Our team works with customers to maintain their legacy products and bring new and developing products to market.

Our team understands every step of the design and manufacturing process. We depend on our depth of experience and scope of industry expertise to improve the quality of products while lowering development expenses and turnaround time. Every assembly we manufacture undergoes incoming inspection, quality assurance testing, and in-process auditing.

Our manufacturing capabilities give us the flexibility to serve customers. We rely on highly-advanced equipment and custom manufacturing software to lower overhead and offer custom solutions at a competitive price. Our wire harnesses and cable assemblies are custom-made and require high-end equipment, tooling, labor, and material compared to off-the-shelf solutions. We offer customers high-quality products at a lower price by depending on our supplier relationships and systems to reduce lot sizes and lead times.

Wire Harness vs Cable Assembly

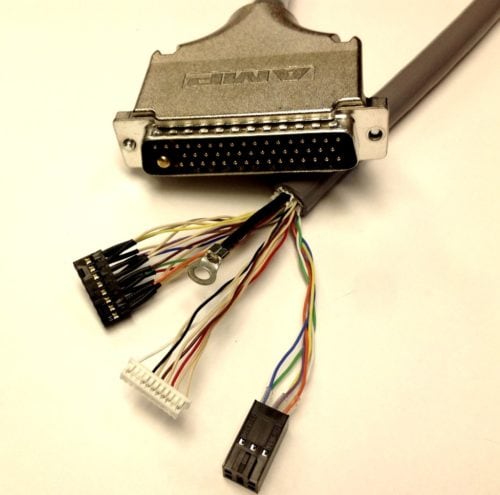

A wire harness and cable assembly are similar in function but have different constructions to perform specific applications. A wire harness is a thermoplastic or thermoset exterior sheath that protects wires or cables from external factors. They also provide organization for cables that already have sufficient protection from the elements.

A wire harness and cable assembly are similar in function but have different constructions to perform specific applications. A wire harness is a thermoplastic or thermoset exterior sheath that protects wires or cables from external factors. They also provide organization for cables that already have sufficient protection from the elements.

Cable assemblies often have a heavy-duty construction of vinyl, thermoplastic rubber, or thermoplastic shrink-wrap. While they protect and organize wires or cables much like a wire harness, they are made to perform in harsh environments.

Wire harnesses are an affordable solution for organizing and grouping wires or cables. They improve connectivity and prevent disorganization, but their load capacity is limited by the number and size of the cables. They are designed for indoor use, and cannot withstand moisture, friction, dust, or extreme temperatures.

Cable assemblies offer ideal protection for outdoor use and harsh conditions. They protect and cover the wires or cables with a thermoplastic, vinyl, or rubber construction. The assemblies can be custom-made to withstand chemicals, friction, dust, moisture, or extreme temperatures. Industries like electronics, military, aerospace, healthcare, and oil & gas rely on rugged cable assemblies of various shapes and dimensions.

Wire harnesses and cable assemblies each have a range of ideal applications. Wire harnesses offer suitable performance for indoor wire or cable organization at a low price. Cable assemblies are preferred for protecting outdoor cables and wires in various extreme conditions.

Why Choose SOS Manufacturing for Custom Cable Assemblies and Wire Harness Manufacturing

SOS Manufacturing has been manufacturing custom cable assemblies and wire harnesses since 2005, and our leadership team that has over 120 years of combined industry experience. Our manufacturing process includes design approval and first article inspection to ensure each part is made to the client’s exact specifications. We design for efficient manufacturability and provide clients with support for manufacturing design.

Our capabilities allow us to manufacture products of the highest quality. We maintain the following quality certifications:

- CSA

- UL

- RoHS

- IPC/WHMA-620

- TUV

- Battery Cable

- Cat 5

- Cat 6

- Coaxial Cable

- Control Cable

- Data Cable

- Flat Ribbon Cable

- Interface Cable

- Lead Wire

- Power Cable

- Ribbon Cable

- Sensor Cables

- Wire Harnesses

Custom Wire Harness & Cable Assembly From SOS Manufacturing.

When you contact SOS Manufacturing, our sales and engineering team works to understand your project’s needs from end to end. We highlight key issues and offer solutions before returning your quote with a price and lead time estimate you can rely on. We deliver a first article inspection report for your approval before building and shipping your order. Our electro-mechanical build team can also build the box or panel for your finished product and install the wire harness. Finally, we kit the product with instructions or brochures before delivering it to you.

To learn more about our custom wire harness and cable assembly capabilities, contact us today or request a quote to get started.